Vision Inspection System

This system can be implemented in autonomous stations but also in apps for smartphones or tablets; it can also be combined with pre-existing vision systems on automatic or manual lines.Skills

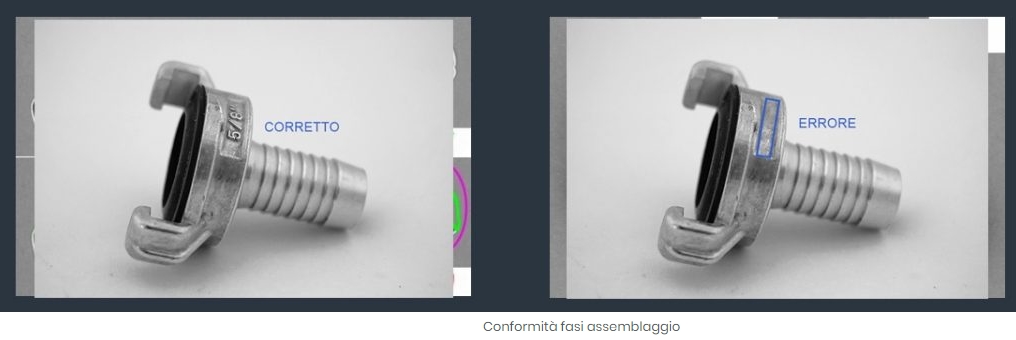

-Assembly check and identification of deformed parts

- Reading of letters

- Assessment of defects

- Texture and material grouping

- Identification of components

-Test compliance, objectification

- Warehouse optimization

- Analysis of similar or interchangeable products

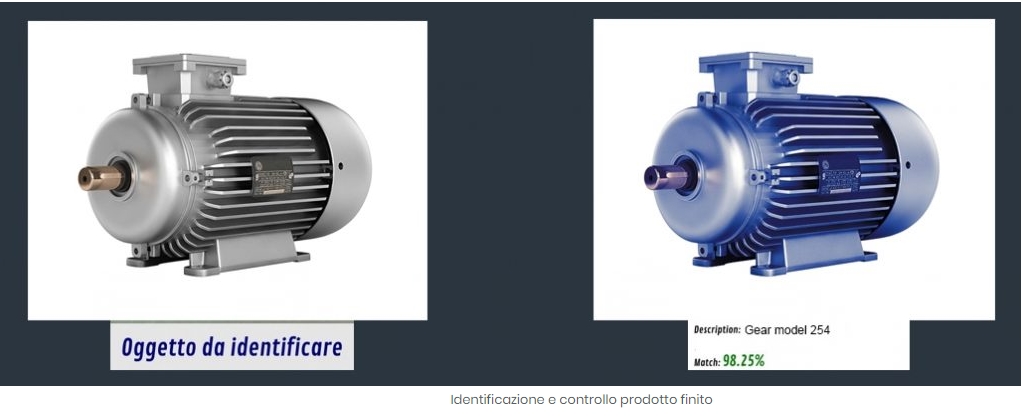

Identifies the product

Identifies a product of any type or size within a set of similar items to be identified by range.

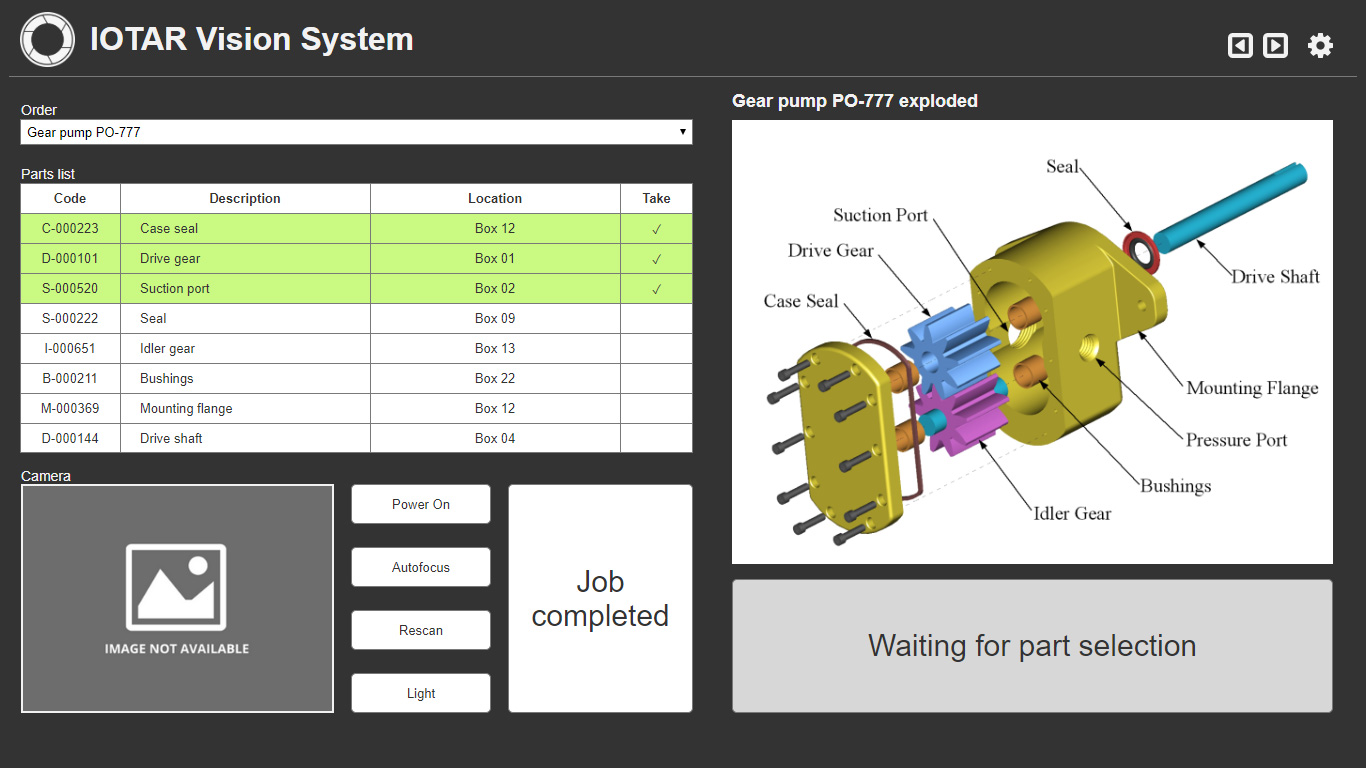

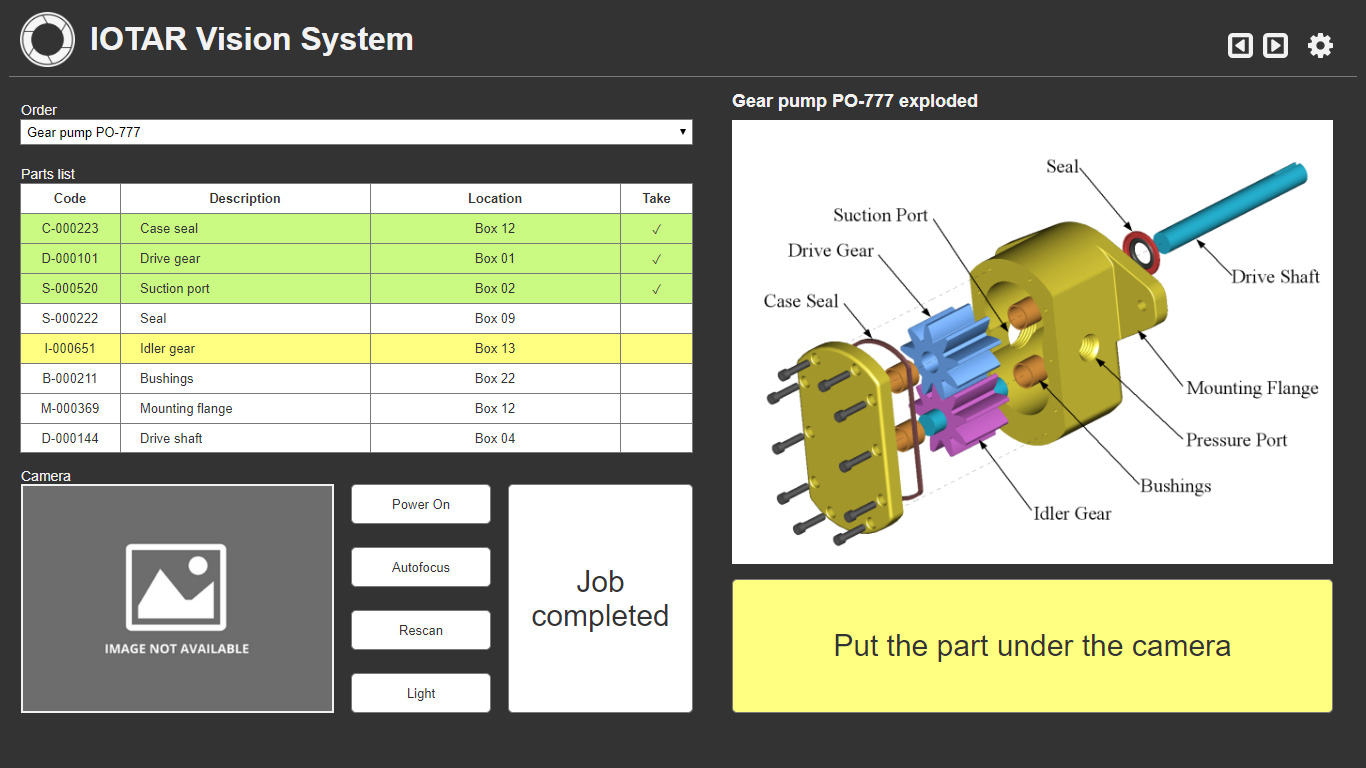

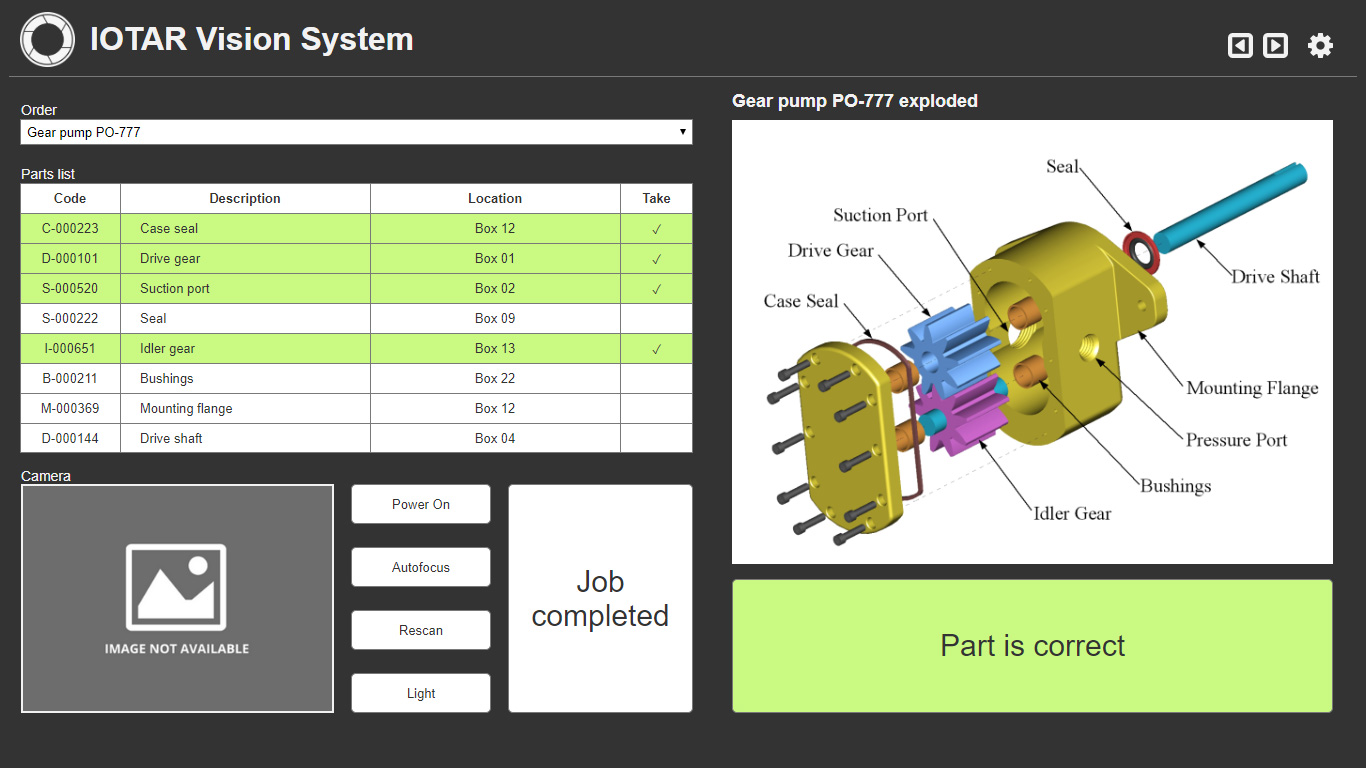

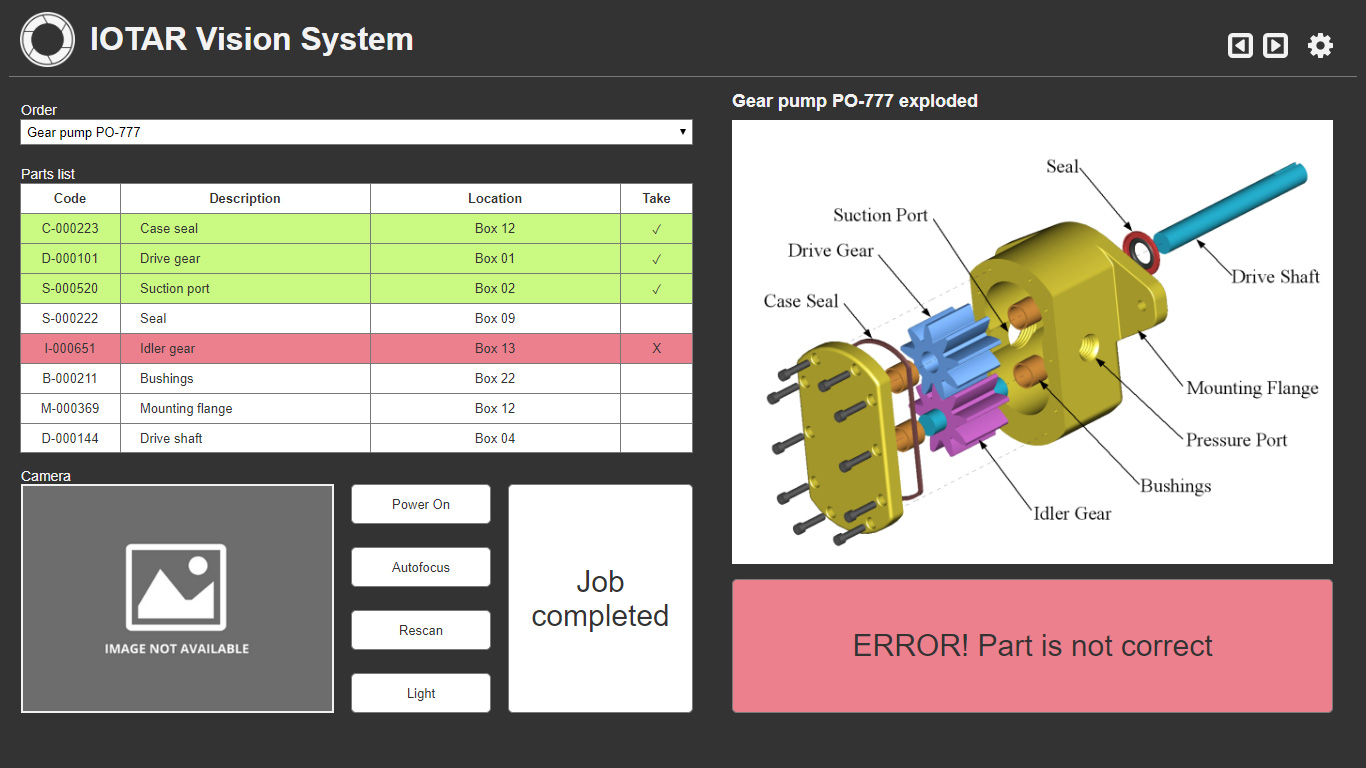

Manual assembly check

IOTAR is used to check the progress of production in each manual assembly station and suggest to the operator the next steps or errors in real time.

Check online

If integrated into the line, IOTAR can automatically detect production defects (e.g. folds and/or dirty or broken fabrics, double weft, missing or torn thread, dimensional checks) and manage waste or production stop logics in the most serious cases.

Finished product quality control.

IOTAR checks product quality for you, identifies production non-conformities in order to highlight defects and manage stock in the fastest and most efficient way possible.

IOTAR SUITE

Discover all the potential of IOTAR SUITE the solution of modular products that give you the possibility to acquire data from the plants and monitor your production from any mobile device.

Production, factory planning, assembly, work safety, digital testing and prototyping, remote maintenance are just some of the cases of use possible with the IOTAR suite.