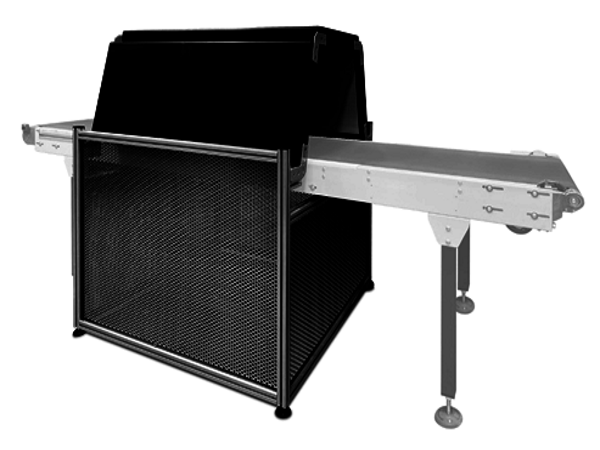

RFID TUNNEL

Traceability, Localization, Access control

Indevo’s UHF Tunnels are structures designed for the identification of pallets/goods in transit

Indevo’s UHF Tunnels are structures designed for the identification of pallets/goods in transit

We have been developing custom projects based on RFID technologies for over 10 years.

We provide consultancy, provide the most suitable RFID solutions and post-installation assistance in Italian.

Our experience allows us to develop customized RFID systems even in those areas where radio frequency signals are difficult to use, such as in the presence of metal plates, which tend to shield the signal.

Indevo’s UHF tunnel has been designed to work with any conveyor belt. An entrance door with metal bulkheads positioned at the beginning of the tunnel allows you to perfectly read the different moving parcels even if close together.

The metal mesh on the side of the tunnel prevents the reading of unwanted tags near the tunnel.

Thanks to the special RFID antennas that have advanced technical characteristics and high performance, it is possible to have an extremely reliable and stable reading on packaged items by focusing the radio frequency field so as to penetrate deeply inside the boxes.</p >The dimensions are customizable. Constructed from lightweight aluminum and stainless steel, it is the market leading solution.

|

Operating frequency |

865-868 MHZ (EU), 902-928 MHZ (USA) |

|

External dimensions (l X W x H) |

1500 X 1200< br /> |

|

Maximum internal dimensions (W x H) |

550 X 500 mm |

|

Minimum length of the conveyor belt </p > |

2000 mm |

|

Weight (Tunnel only)</p > |

ca. 100 kg |

|

Distance between parcels* |

Recommended 500 mm |

|

Typical speed conveyor* |

In 24m/min |

|

Interface |

Ethernet 10/100 BaseT |

|

Data format |

EPC followed by CRLF in text format APIs available with REST call |

|

Food (V) |

Reading unit: 24Vdc 2.0A |

|

Typical power consumption |

ca. 50w |

|

Temperature |

From 0°C to +50°C |

|

Display |

Upon request |

RFID systems are subject to incentives for industry 4.0

Get the best solution for your business

RFID solutions can be used along the entire production and goods handling chain, responding to different needs: