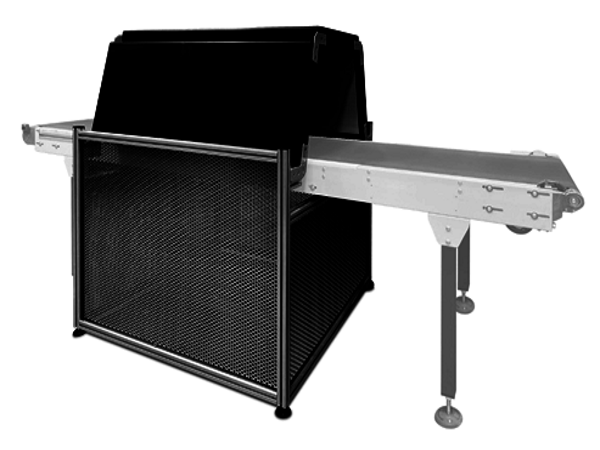

Solutions for industrial laundries

Traceability of garments, quality control and broken and dirty

The solutions for industrial laundries simplify management by bringing a new intelligence that, through quality control and traceability of linen, allows them to better respond to the logistical needs typical of this type of service.