MES NET@PRO

Production Management, Monitoring, Control and Planning

The first MES management system in Italy that respects the principles of Industry 4.0

The first MES management system in Italy that respects the principles of Industry 4.0

NET@PRO is the MES that speaks 7 languages, active 20,000 users every day.

We are authorized distributors of Qualitas MES NET@PRO.

We help manage your factory in an integrated way with a system that allows your assets to communicate according to Industry 4.0 standards.

For manufacturing companies that want to have real-time production control, we provide a 360° Software that guarantees maximum production efficiency.

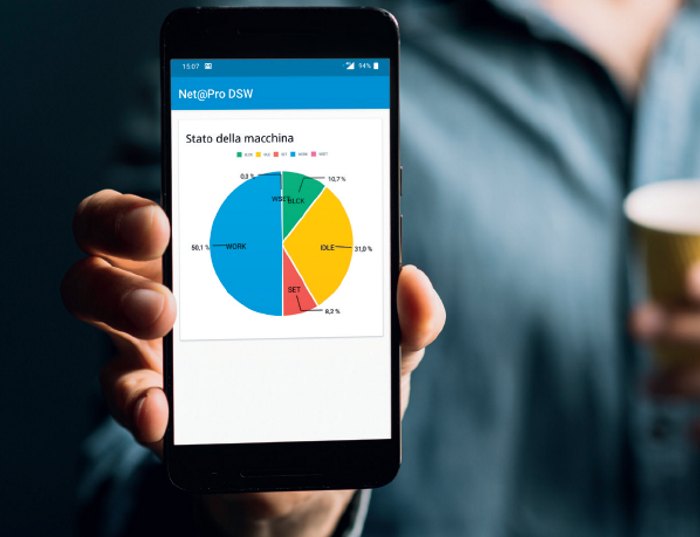

The NET@PRO system allows data collection and activity monitoring through a dashboard for real-time productivity indicators.

It allows planning from short-term to medium/long-term production planning using special tools

which allow the management of the needs of materials and capacities.

The MES NET@PRO System, easy to integrate and bidirectionally interconnect with departmental machines according to the prerequisites of Industry 4.0, is ideal for traceability and complete warehouse management.

In addition to the department machines, the MES NET@PRO software is easy to integrate with external systems such as ERP, APS, CPM. This ensures a smooth and agile exchange of information with other business systems.

The NET@PRO Software speaks 7 languages and is the only MES software to have advanced pre-configured models created by drawing on 30 years of manufacturing know-how in over 20 industrial sectors.

Experience in more than 20 industrial sectors:

• Food&Beverage

• Forging, stamping and

metal working

• Machining

• Machinery and plants

• Wood and furniture

• Plastic

• Electric motors

… and many others

INCENTIVES FOR INDUSTRY 4.0

NET@PRO is the MES that implements smart manufacturing and allows you to obtain industry 4.0 incentives

Full Web, Real Time, Simulation, Proactive and Always Updated.