APPLICATIONS

Plants, Traceability and Special Projects

Indevo’s experts are at your side to develop the right solutions for your company’s needs

Indevo’s experts are at your side to develop the right solutions for your company’s needs

For over 15 years we have been developing projects, plants and machines for companies

Our experience enables us to develop tailor-made systems for production and logistics.

We consult and provide the most suitable solutions for your needs.

The end-of-line systems typically used in the production and logistics sectors are used in the order preparation phases which go from the packaging of the material to its sorting along the palletizing lines or more generally towards the exit and shipment.

Indevo s.r.l. designs and builds end-of-line systems or palletizers managed by customizable software: we can supply common palletizers or design them according to customer needs, adapting them to the production line. The end-of-line palletizer manages boxes, bags, bottles, etc. on the pallets, arranging them according to the instructions sent by the software. Palletization management is global and in some cases it is possible to place objects or packages of even different sizes on the pallets.

The Handling and Sorting systems are designed to facilitate decoding and sorting operations of large volumes of parcels, according to specific and variable criteria. These systems were created for the recognition of the barcode but are also designed to acquire and archive the images of the processed packages thanks to the implementation with special cameras.

Handling systems are used in all phases of the production and distribution cycle: from the management of raw materials to warehouse handling, from storage and order preparation to loading onto means of transport.

With these systems, the increased productivity and efficiency gains will be readily apparent. Not to be overlooked is also the optimization of warehouse spaces which will immediately take on a more orderly appearance.

Do you need a customized packaging and labeling system? Indevo s.r.l. it suits you. Thanks to our knowledge and decades of experience in the sector, we can create packaging and labeling systems that use devices for collection, sorting, pick to light, and the check of items for identifying the contents of the packages . Transportation of the goods is provided by special handling belts, shuttles or bridge cranes, while wrapping machines, taping machines and heat-shrinking ovens are more commonly used for packaging. Finally, we supply identification, weighing, labeling systems and system management software. Obviously, our software can also be created on the basis of specific customer needs.

They are designed for the management of the entire plant, in fact they interface with the company management system for the two-way exchange of data.

For the handling and palletizing of packages, we suggest our robots for collaborative operations equipped with grippers suitable for gripping the packages. The latter are transported to the end of the packing line.

Our robots for collaborative operations are designed for the automatic treatment of goods, in fact, thanks to the association with barcode readers, they can independently identify the products. They can work with boxes, bags, crates and are ideal for various towing tasks, such as moving heavy products between different areas of a facility.

Furthermore, thanks to our ZWMS software, it is possible to track the movement of your goods within the warehouse. We are able to provide you with robots equipped with RFID technology, to monitor the goods even when they are traveling!

Thanks to our systems, we are able to inspect and verify fabrics (broken, dirty).

Our instrumentation can handle the manual or automatic measurement, weighing and labeling of the fabric, even identifying defects such as deterioration, breakage or the presence of stains on the fabrics themselves. Many companies have to manage thousands of garments every day and for this reason they need to automatically identify dirty or broken garments before, after or during the processing cycle to guarantee the highest quality to their customers.

For this reason, our company has created vision systems designed for fabric control, crease detection, dirt and automatic defects.

We also provide you with a report and follow you in the interfacing phase with your company’s management system.

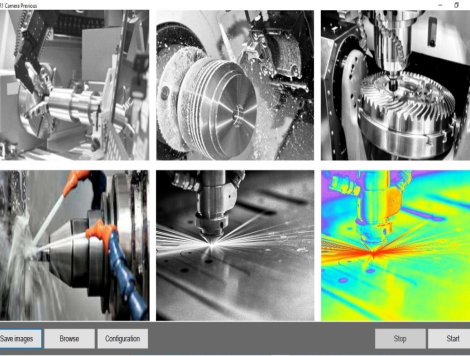

We have developed an ad hoc solution capable of managing Prosilica and Basler cameras that allows simultaneous viewing of 6 cameras.

With this hardware structure we were able to guarantee the acquisition with the maximum frame rate (about 30 frames per second) without any lost frame.

In this program you can configure up to 6 cams by IP address. With this program it is possible to send to Labview a series of commands, which can be edited according to the program, on the Start and Stop recording events. Using the Save images button, all the previews present on the cameras are saved at any time. They are saved in a user-defined folder. Finally, we added the ability to “crop” the affected area for each cam.

We can provide you with a weight-based object identification system. The operator who wishes to identify the object places it in the identification system. The latter recognizes the object through its weight; once the object has been identified, it is established in which basket to place it. If the identified object does not appear to be compliant, our system will detect an inadequate identification of the object.

The complete management of the whole system is based on the use of our IOTAR Inspection System which interfaces with the competent operators and technicians. The system created by our company together with the experience and commitment of our staff have made it possible to obtain a highly efficient system for the identification and location of objects, with full satisfaction of the customers to whom we have supplied it.

Our company has increasingly developed the ability to design, implement and manage complex and critical technical infrastructures. Skills proven by the design experiences gained in recent years in various technologies.

We have created an automated system capable of simplifying and improving the steps of the packaging chain. The system we provide takes care of introducing the raw materials into the production chain, processing them through the machinery, tracing the positioning of the goods on the rolls before enveloping and subsequent distribution through couriers used for transport. All monitored by an ad hoc supervisory system of the plant.

It is extremely important for us to point out that all data is collected in real time.

Our specialists have developed projects designed to solve the problem of barcodes that deteriorate easily or are subject to poor legibility due to stacking of products. The proposed solution is to equip each product in the warehouse with a passive RFID and each forklift with an RFID reader and a camera. With RFID, all traceability problems can be completely solved with special programs integrated with the information system. Furthermore, with the camera it is possible to record the movements of the forklifts, suggest the best itineraries and prevent errors in picking up the goods. All enriched by the IOTAR application, a solution designed to meet the needs of companies to equip themselves with an integrated, reliable and flexible system for collecting, storing, displaying and analyzing data from the field.

Indevo can supply a wide range of devices for reading and storing barcodes. Fixed line readers, manual laser readers, built-in readers, cordless manual readers that interface with computers or the company management host. The ZA8C7X portable readers supplied by Indevo guarantee sturdiness, practicality, lightness and IP65 protection. Suitable for resisting falls and harsh environments such as industrial or outdoor.

With Android operating system, integrated quad-core processors and 4G, Wi-Fi and Bluetooth communication systems, these devices can be implemented in various industrial needs. The supply is completed with batch portable terminals that collect all the data collected in their internal memory or with WIFI radio frequency portable terminals connected to the company network. We are also able to create software suitable for all business needs (traceability, warehouse management, production management, and much more).