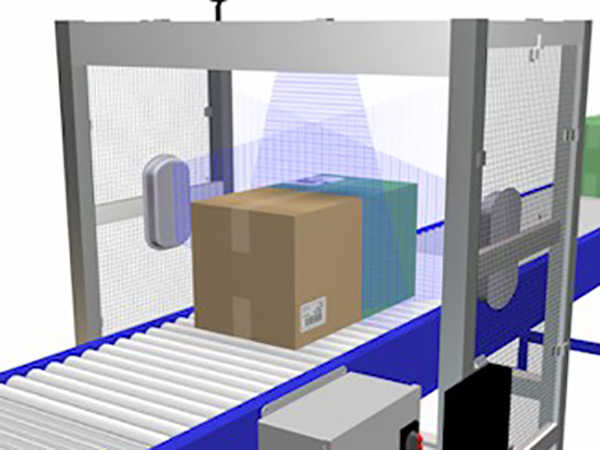

Solutions for the textile sector

Quality control and traceability of garments

The solutions for the textile production sector simplify management by bringing new intelligence which, through the quality control and traceability of the garments, allows us to best respond to the logistical needs typical of this kind of service.