Sistemi di visione industriale

I sistemi di visione industriale possono essere attuati in stazioni autonome ma anche App per smartphone o tablet; inoltre possono essere congiunti a sistemi di visione pre-esistenti su linee automatiche o manuali.Skills

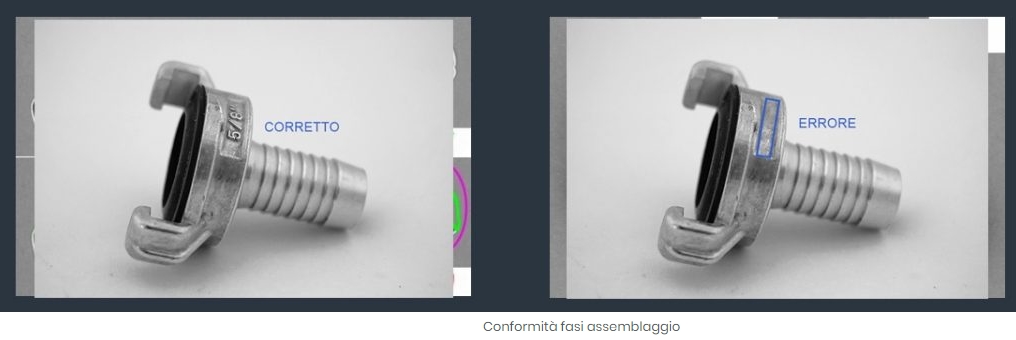

-Controllo assemblaggio e identificazione delle parti deformate

-Lettura di lettere

-Accertamento di difetti

-Raggruppamento di texture e materiale

-Individuazione componenti

-Test conformità, oggettivazione

-Ottimizzazione del magazzino

-Analisi di prodotti analoghi o interscambiabili

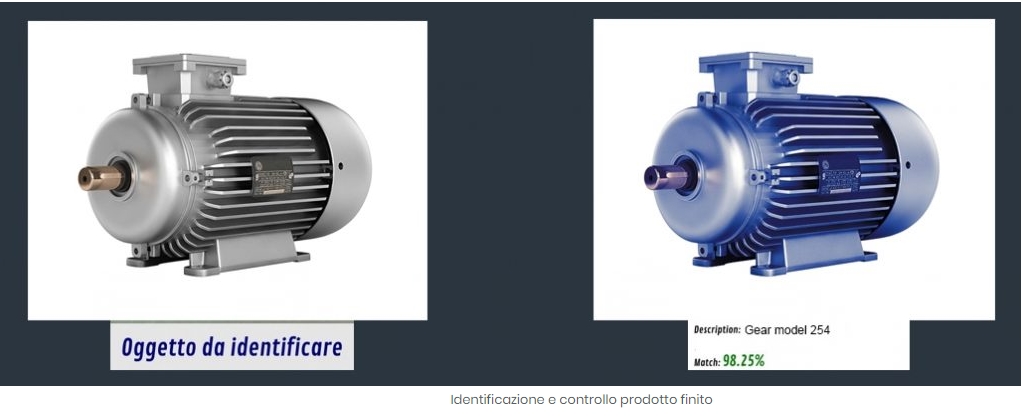

Identifica il prodotto

Identifica un prodotto di qualunque tipo o dimensione all’interno di un insieme di articoli similari da identificare per gamma.

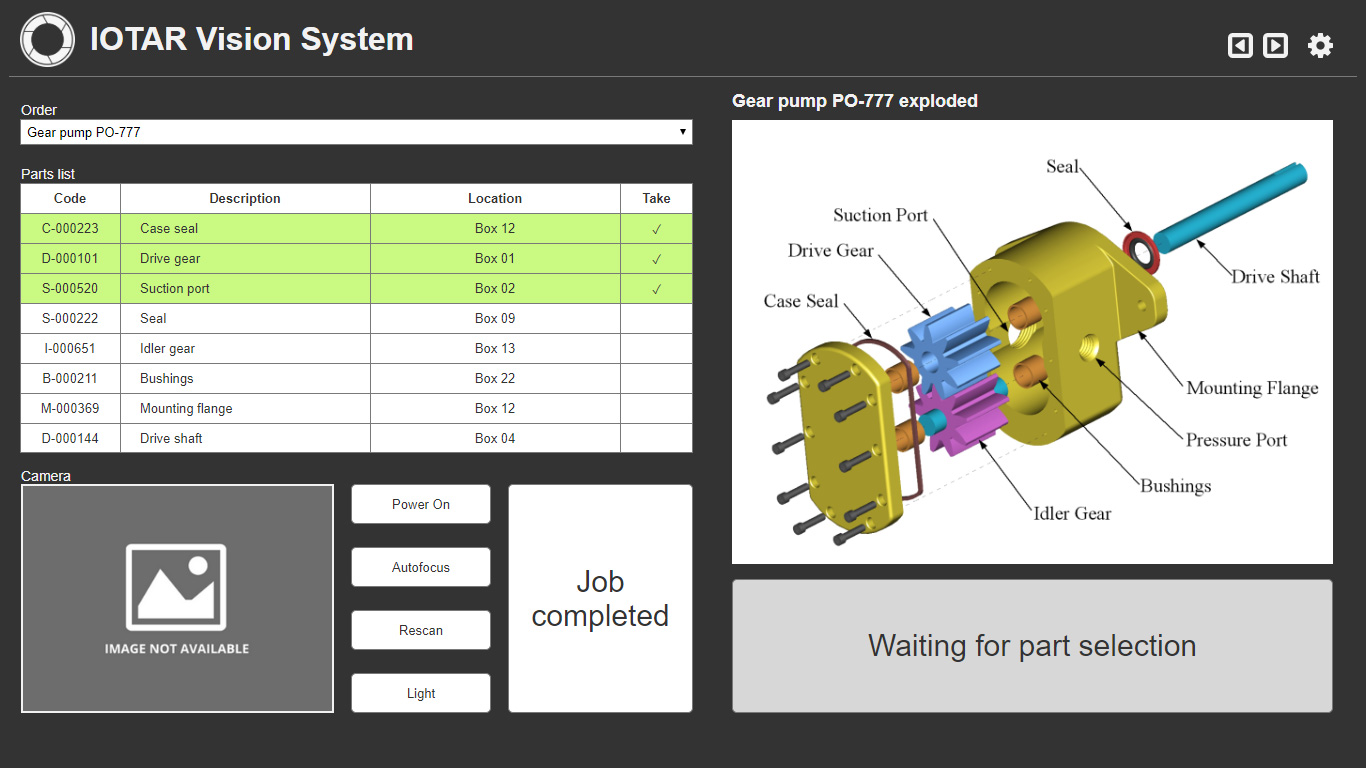

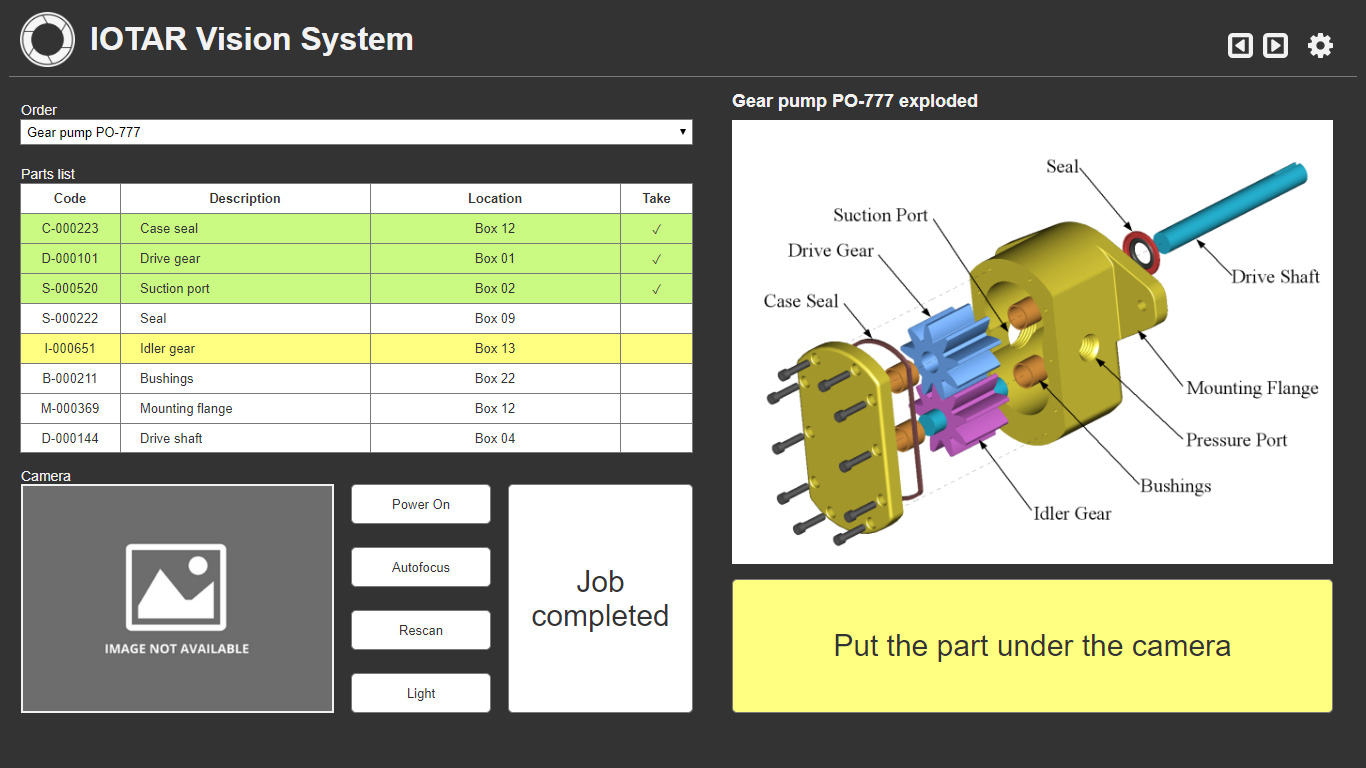

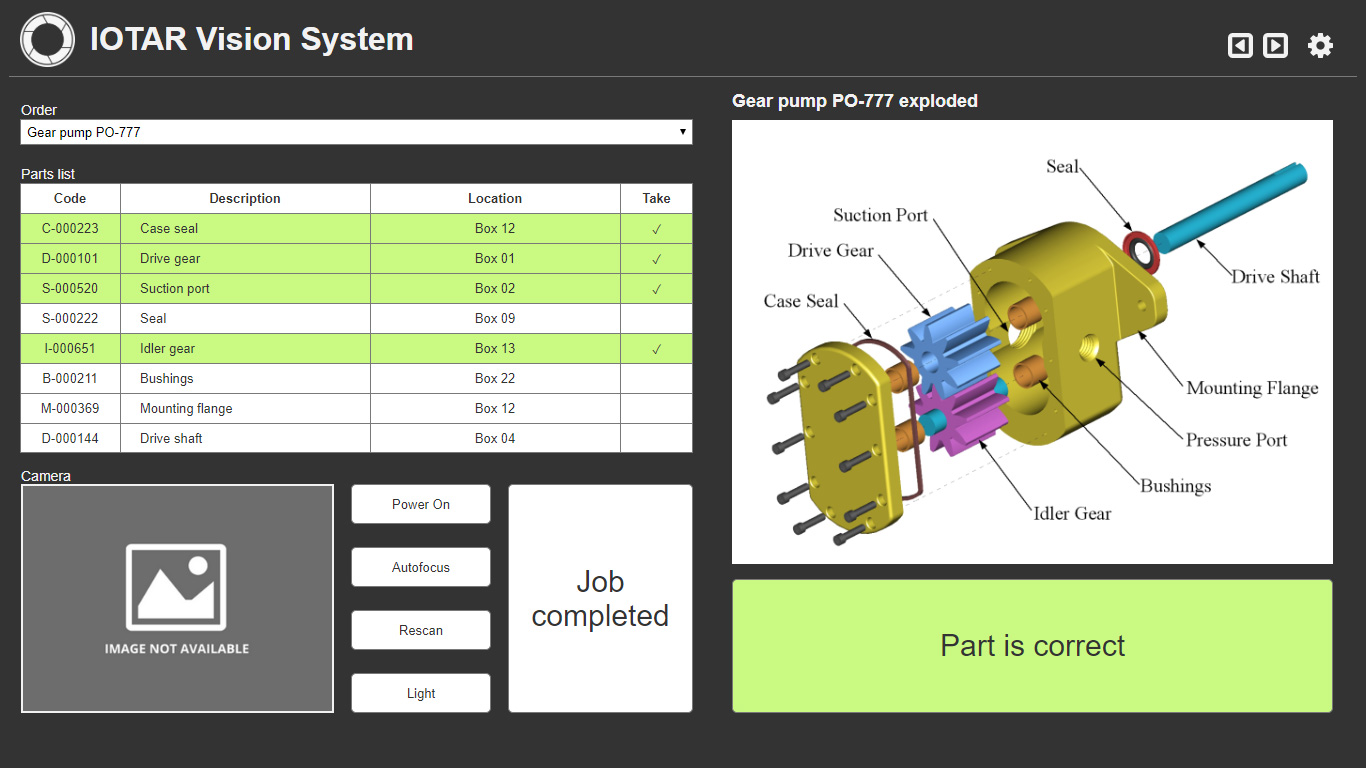

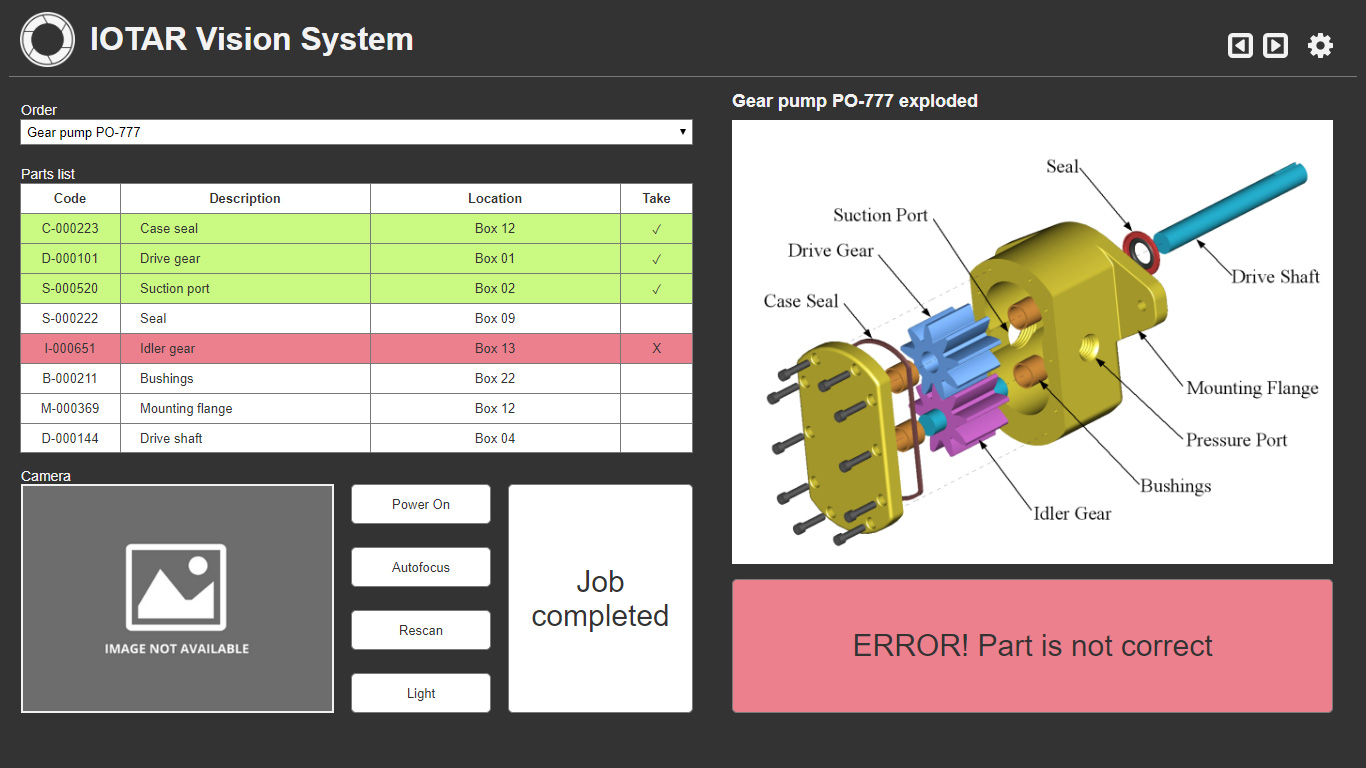

Controllo assemblaggio manuale

IOTAR è utilizzato per controllare l’avanzamento della produzione in ogni postazione di assemblaggio manuale e suggerire all’operatore i passaggi successivi o errori in tempo reale.

Controllo in linea

IOTAR se integrato in linea può rilevare automaticamente i difetti di produzione (es. piega e/o tessuti sporchi o rotti, trama doppia, filo mancante, strabattuto, controlli dimensionali) e gestire logiche di scarto o fermo produzione nei casi più gravi.

Controllo qualità prodotto finito.

IOTAR controlla per te la qualità del prodotto, individua le non conformità della produzione al fine di evidenziare i difetti e gestire lo stock nel modo più veloce e performante possibile.

IOTAR SUITE

Scopri tutte le potenzialità di IOTAR SUITE la soluzione di prodotti modulari che ti danno la possibilità di acquisire i dati dagli impianti e di monitorare la tua produzione da qualunque dispositivo mobile.

Produzione, pianificazione di fabbrica, assemblaggio, sicurezza sul lavoro, test e prototipazione digitale, manutenzione a distanza, sono solo alcuni dei casi d’uso possibili con la suite di IOTAR.