Z Automation: we help companies improve the performance of quality standards

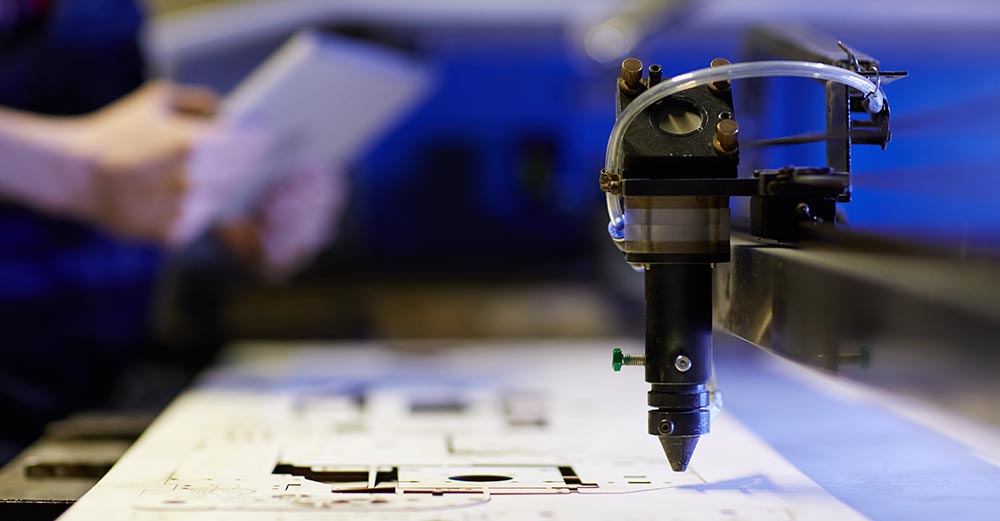

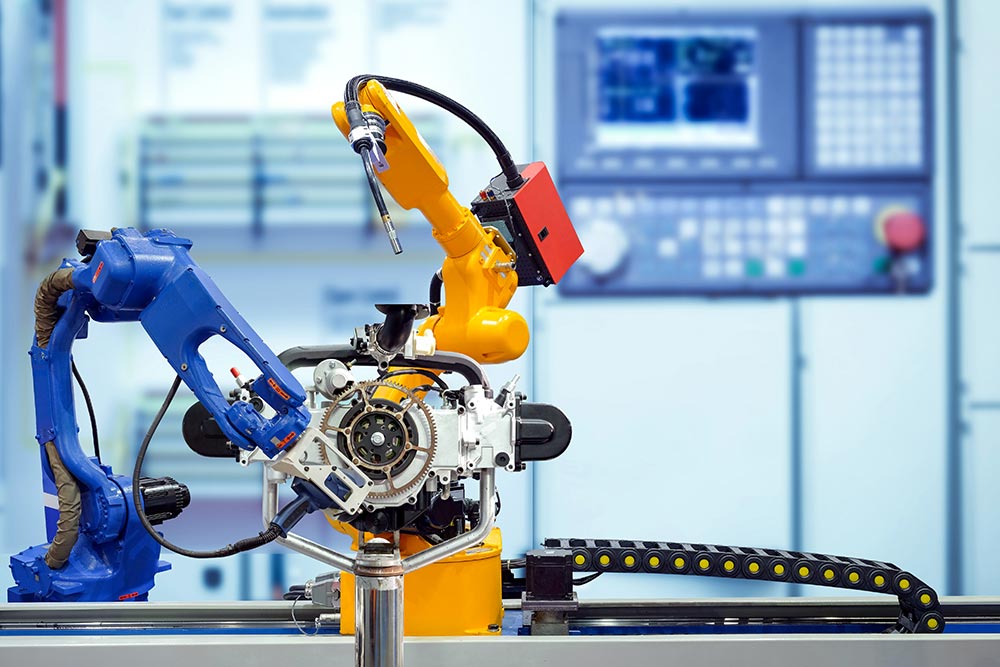

In the Artificial Vision sector applied to industry, we create Vision systems that can be easily integrated with your industrial equipment to optimize the quality standards of your systems.

Consulting and development of vision systems

We can provide you with our consultancy or pre-packaged products to develop vision systems, image acquisition, pre-processing, motion recognition, shape and frame recognition, high-level processes, speed detection, engine rpm detection, quality control, industrial automation and much more other.

We program and interface with almost all types of PLC and, for this reason, we are able to support the customer in the technological choice.

Machine vision systems can be easily integrated with existing machines, and theirs cameras, can carry out the following checks in automatic or semi-automatic mode:

Dimensional control systems and defects

Product quality control systems

Robot guidance systems

Effective, long-lasting and “turnkey” Artificial Vision systems: for maximum return on customer investments

We create and design Artificial Vision and robotic systems, with maximum control of application know-how and software development. We guarantee complete assistance and future upgrades of the solutions identified with the customer, in order to obtain certain profitability on the investment.

Turnkey solutions thanks to a top-level partner and leader in the Industrial Vision sector

We create cutting-edge industrial vision solutions, using the best manufacturers and standards on the market (Beckhoff, Keyence, Dahua, Baumer, Dalsa, Allied Vision, LMI, OpenCV, HALCON, etc.).

We also count our official collaboration with the companyStemmer Imaging, one of the leading European suppliers of machine vision technology, such as vision systems, illuminators, cables and software.

Choose to increase the performance of your production

with Industrial Vision Systems

Fill out the form and request a consultation:

we will develop the most suitable project to optimize your processes and resources!

Most common types of industrial vision controls

ARTIFICIAL VISION ALGORITHMS with solutions modeled on customer needs

Quality controls in PPM

Multiple quality checks simultaneously, for example the correct assembly, the presence of defects, the legibility of brands and writings. Visit our product page IOTAR Vision inspection system for Inspection and control of products.

Surface analysis

A series of particularly advanced algorithms allow you to check surface defects such as beating, porosity, opacity, grit, dirt, cracks, peeling or scratches. Visit our product page IOTAR Vision inspection system for product inspection and control.

Production line measurement

Measurements can be performed directly during production, checking 100% of the pieces. Precision is micrometric, repeatability and accuracy are calculated in real time in order to compensate for any changes in the environment. Visit our product page IOTAR Vision inspection system for product inspection and control.

Robot guide

The robot guide is the software module which, using advanced logics, both for 2D and 3D gripping, allows the correct identification of the object in space.

Datamatrix reading, OCV OCR

It is possible to read the codes printed on the inspected piece, save the image and analyze the information contained therein. These machines can also be equipped with a branding system to objectify the product.

Choose to increase the performance of your production

with Industrial Vision Systems

Fill out the form and request a consultation:

we will develop the most suitable project to optimize your processes and resources!

Our machine vision system:

IOTAR Vision inspection system

Industrial vision systems can be implemented in autonomous stations but also Apps for smartphones or tablets; furthermore they can be combined with pre-existing vision systems on automatic or manual lines.

We have decided to concentrate all company efforts on consolidating and expanding the application experience, using the best of specialized world production, through continuous work of technological updating.

Not being linked exclusively to any single supplier or any major brand on the international market for the preparation of one’s systems represents for Z Automation the best and most concrete guarantee of absolute quality, which it can offer to its customers.

TO THIS PURPOSE WE CREATED AND DEVELOPED IOTAR:

A choice of seriousness, but also of freedom, to be able to range without constraints and conditionings in the entire techno-product panorama available on the market, so as to always guarantee the best result.

IOTAR Vision inspection system: SKILLS

Assembly control and identification of deformed parts

Reading letters

Finding defects

Grouping of textures and material

Identification of components

Conformity test, objectification

The unique features of

IOTAR Vision inspection system

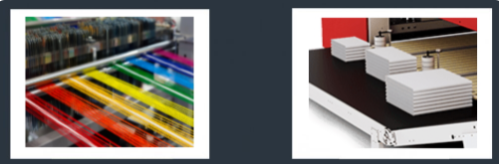

1. Identify the product

Identifies a product of any type or size within a set of similar items to be identified by range.

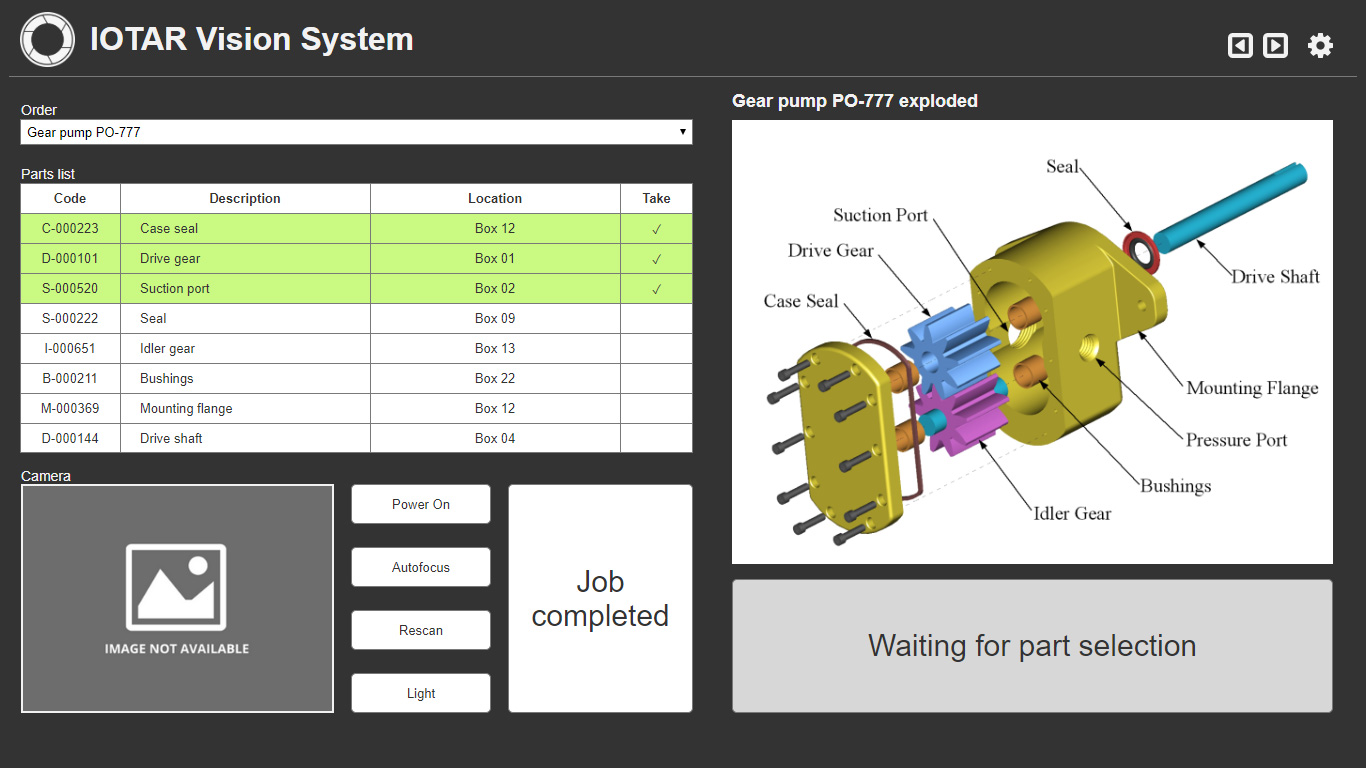

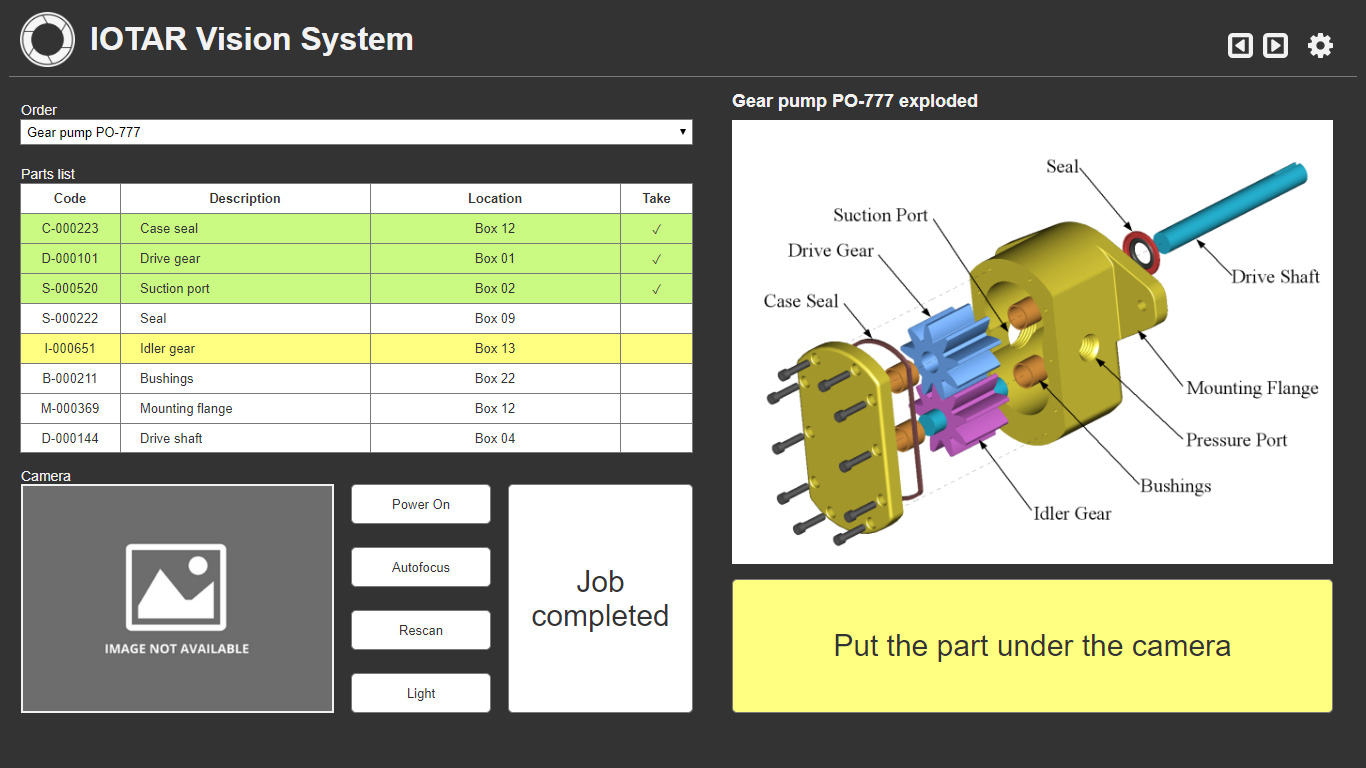

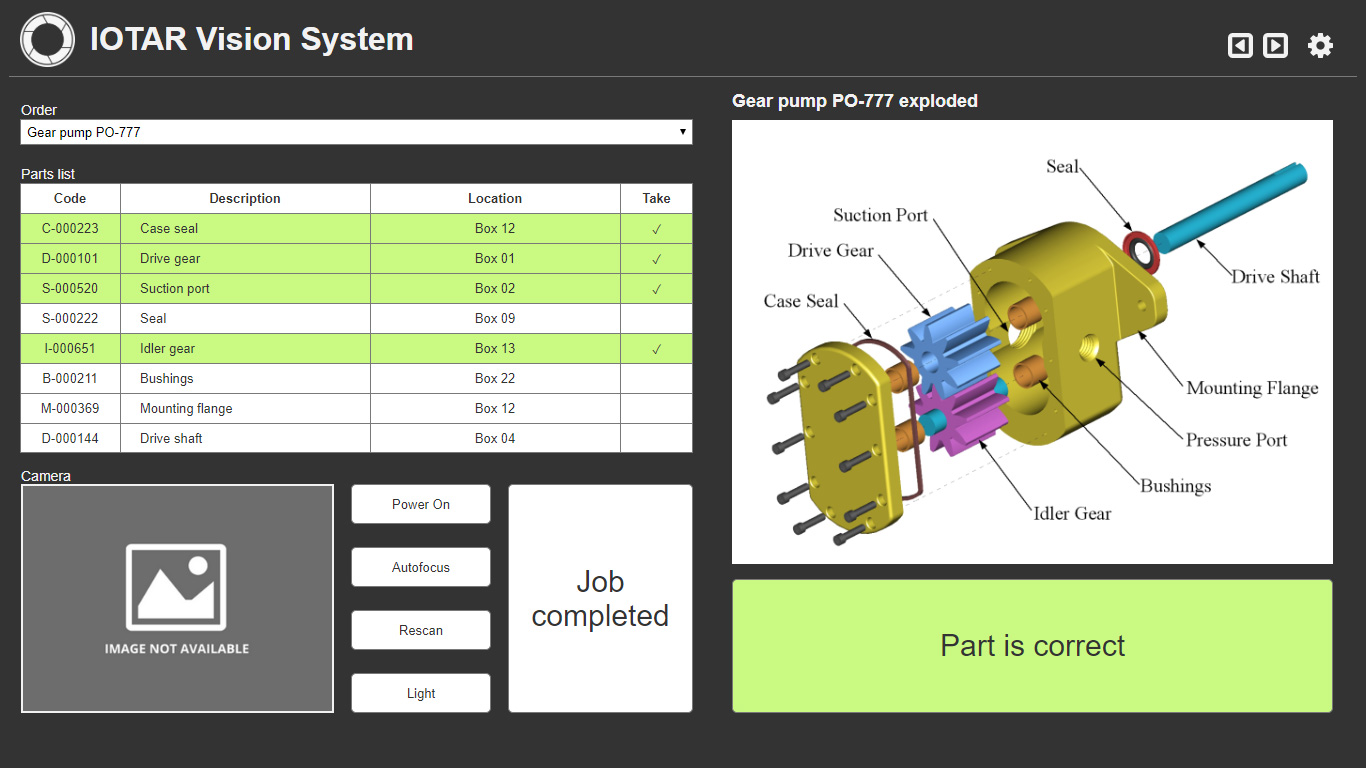

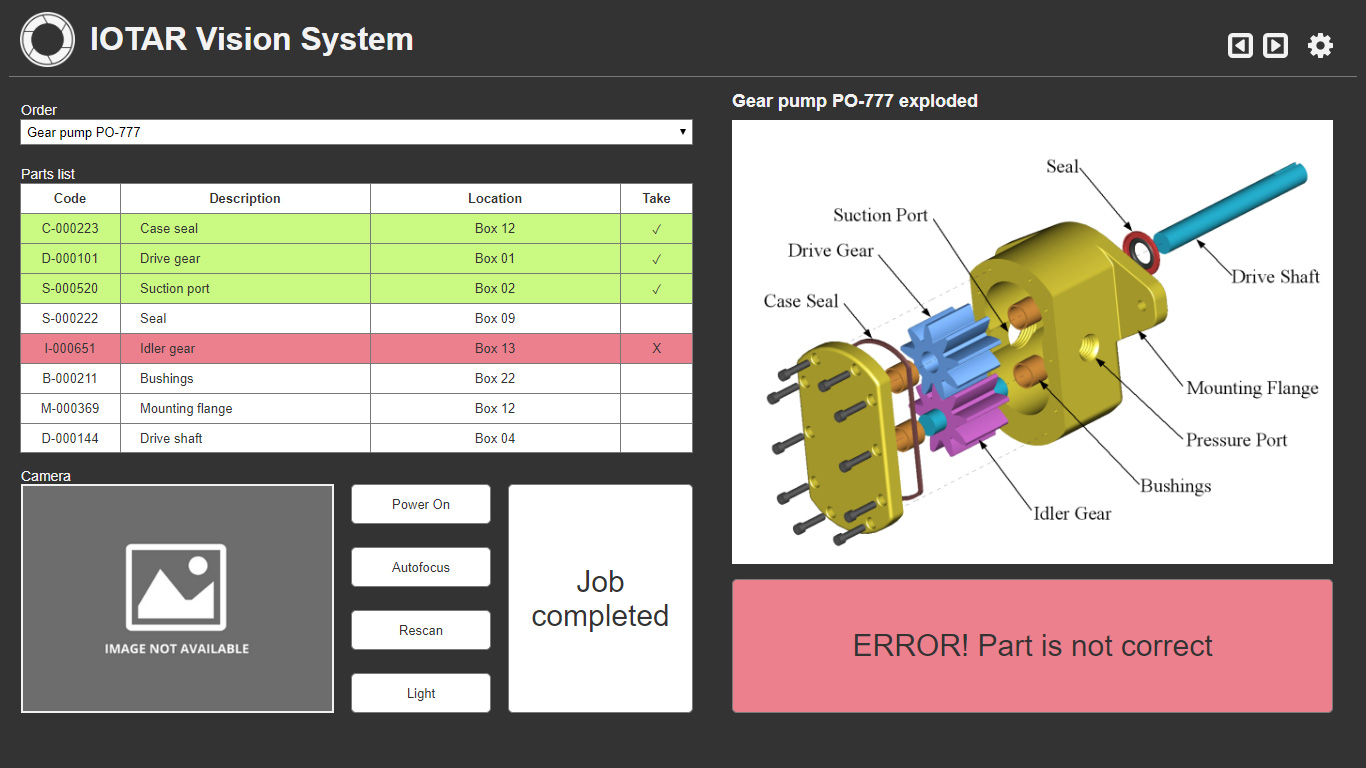

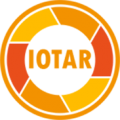

2. Manual assembly control

IOTAR is used to check the progress of production in each manual assembly station and suggest the next steps or errors to the operator in real time.

3. Inline control

IOTAR, if integrated into the line, can automatically detect production defects (e.g. folds and/or dirty or broken fabrics, double weft, missing or straggling thread, dimensional checks) and manage waste logic or production stop in the most serious cases.

4. Finished product quality control.

IOTAR checks product quality for you, identifies production non-conformities in order to highlight defects and manage stock in the fastest and most efficient way possible.

IOTAR Vision Inspection System

for assembly control

IOTAR can control all product assembly phases by suggesting to the operator the correct sequence and the parts to use in order to speed up the production and avoid assembly errors.

IOTAR SUITE

Discover all the potential of IOTAR SUITE the solution of modular products that give you the possibility to acquire data from the plants and monitor your production from any mobile device.

Production, factory planning, assembly, occupational safety, digital testing and prototyping, remote maintenance, are just some of the possible use cases with the IOTAR suite.

Choose to increase the performance of your production

with Industrial Vision Systems

Fill out the form and request a consultation:

we will develop the most suitable project to optimize your processes and resources!

What are the advantages of Z Automation Industrial Vision Systems?

- Accelerate production processes;

- Reduce production costs;

- Complete and flexible systems;

- Contactless;

- Increase in quality standards;

- Custom systems

- Real time data acquisition

Choose to increase the performance of your production

with Industrial Vision Systems

Fill out the form and request a consultation:

we will develop the most suitable project to optimize your processes and resources!