Sistema di acquisizione dati

Un sistema di acquisizione dati è un sistema realizzato per registrare ed eventualmente post-elaborare le misure di una o più grandezze fisiche.

Parlando di sistemi, si intende un insieme di strumenti che, opportunamente collegati e settati realizzano una o più catene di misura. Essenziale per questi sistemi, è che le misure vengano registrate su supporti (solitamente database sql/no-sql) sufficientemente stabili per aver il tempo di analizzarle, o al limite, essere conservate a scopo documentale per un tempo indefinito.

Sistemi di Acquisizione Dati Real-Time

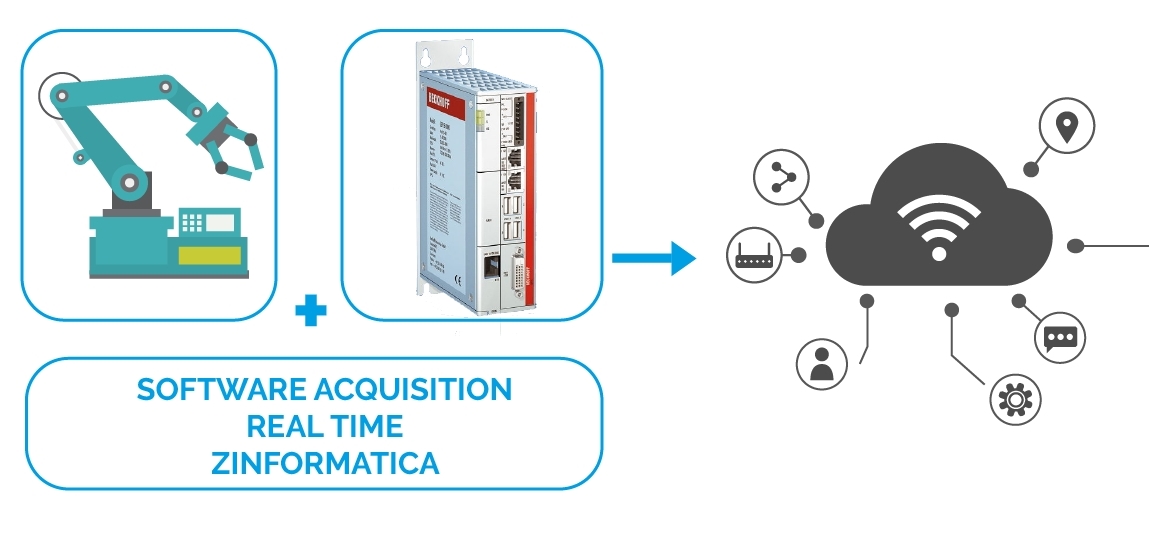

Il nostro prodotto IOTAR Acquisition SW è una black box composta da un'applicazione schedulata con configuratore web volta all’acquisizione e la raccolta dei dati dai PLC in un database centralizzato (cloud pubblico o privato) dalle macchine/database/files del cliente.IOTAR ACQUISITION SW è un Sistema di Acquisizione dati Real-time dai PLC per il rilevamento dei dati (ad esempio pezzi prodotti, stato macchina, tempi di fermo, temperatura, velocità, segnali A/D, pressioni, valori di coppia, segnali ad alta velocità, ecc.) provenienti dalle macchine di produzione; sistemi personalizzati e adatti alle infrastrutture industriali esistenti.

Tutti i dati vengono raccolti dai PLC con il sistema IOTAR Acquisition SW in tempo reale in database SQL o NO-SQL sia in Cloud privati che pubblici. Attraverso un modulo funzionale le nostre soluzioni permettono di spostare e sincronizzare enormi quantità di dati in modo bidirezionale (grazie a un modulo già sperimentato è possibile spostare, attraverso il semplice drag&drop, i dati dal PLC al Database).

Tramite il nostro sistemi di acquisizione dati IOTAR Acquisition SW è possibile:

-Il monitoraggio macchine e risorse di consumo;

-La consuntivazione dei tempi di manodopera (tramite terminali industriali, barcode, RFID, NFC, badge);

-La supervisione delle linee produttive, con rilevazione tempi e fermi macchina (anche con l’innovativa Web App IOTAR);

-Una più efficace pianificazione, programmazione e schedulazione della produzione;

-La gestione delle commesse di progettazione e produzione grazie all’integrazione con l'ERP (Enterprise Resource Planning);

-Il calcolo dell'efficienza produttiva;

-Un attento controllo della qualità;

-L’etichettatura di fine linea;

-La gestione e la programmazione della manutenzione;

-Una più accurata gestione del magazzino e della logistica con tracciabilità merci;

Su richiesta, per le integrazioni particolari con le macchine (PLC - Segnali digitali - Contapezzi - Allarmi) realizziamo software altamente customizzati (prediligiamo le tecnologie Beckhoff, ma siamo in grado di adeguarci alla struttura del cliente) utilizzando le tecnologie VB, C++, C# .NET e su IOT.

IOTAR SUITE

Scopri tutte le potenzialità di IOTAR SUITE la soluzione di prodotti modulari che ti danno la possibilità di acquisire i dati dagli impianti e di monitorare la tua produzione da qualunque dispositivo mobile.

Produzione, pianificazione di fabbrica, assemblaggio, sicurezza sul lavoro, test e prototipazione digitale, manutenzione a distanza, sono solo alcuni dei casi d’uso possibili con la suite IOTAR.