ZAutomation da oltre dieci anni si occupa di progetti custom basati su tecnologie RFID.

Tali tecnologie consentono di incrementare la qualità dei processi e diminuire sensibilmente gli errori; il settore industriale rappresenta uno degli scenari con sviluppo maggiore in merito alla tecnologia RFID e a quella RTLS, infatti esse vengono predisposte per governare i processi interni di produzione, magazzino e spedizione.

Adottare un sistema di identificazione a radiofrequenza consente, a parità di risorse umane impiegate, un aumento della qualità dei processi.

TECNOLOGIE RFID NELLA LOGISTICA

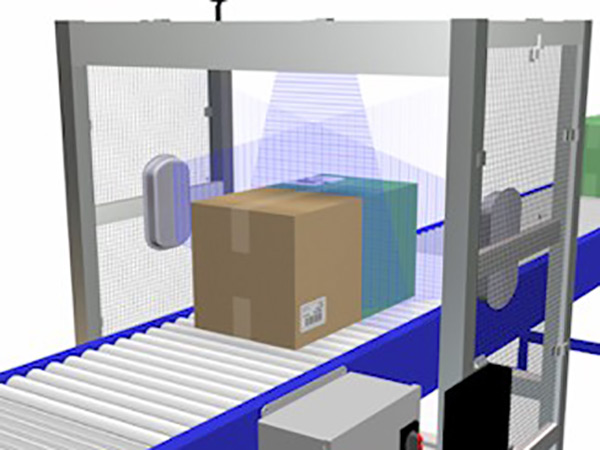

La tecnologia RFID può trovare applicazione nella logistica in quanto permette un approccio completo alle logiche di magazzino e spedizione, tracciando in automatico gli spostamenti tramite l’installazione di reader, oppure tramite l’accesso alle informazioni contenuti nel database.

Nei nostri giorni è sempre più ricorrente il desiderio di accorciare i tempi di produzione e spedizione, proprio per questo motivo la tecnologia RFID viene applicata nelle fasi di produzione, andando quindi a ridurre gli errori nei tempi di controllo delle consegne e di versamento a magazzino.

RFID risulta fondamentale nella mappatura del magazzino, la ricerca ed il prelievo della merce ne risultano velocizzate: in un sistema tradizionale di picking, l’operazione risulta lenta e rischiosa, in quanto basata sulla memoria storica dell’operatore; con l’RFID invece il sistema gestisce e conosce l’esatta ubicazione della merce in magazzino, generando un processo velocizzato, con trasferimento di informazioni sicure ed esenti da errori.

Tra le feature tecnologiche recepite ai fini della logistica, spiccano in ambito UHF i chip con aumentate performance e capacità di memoria. Abbiamo possibilità di studiare e realizzare rfid custom, antenne, rivestimenti e tag/transponder anche con minore sensibilità all’ambiente fisico, ossia liquidi e metalli, e all’orientamento spaziale.

Meno sensibilità all’ambiente e maggiore precisione di lettura significano, in termini pratici, evitare i “falsi positivi”, cioè le letture non desiderate, che sono da considerarsi alla pari di un errore.

Affidati a chi offre consulenza RFID da anni, e scegli la soluzione migliore per la tua azienda.

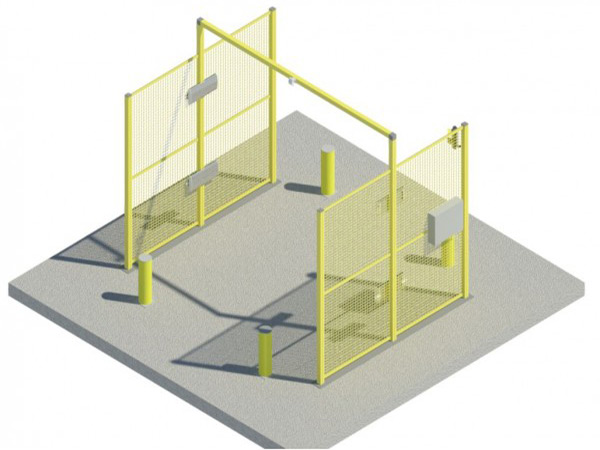

VARCHI E GATE RFID

Con la tecnologia RFID è possibile progettare ed attrezzare gate con lettori UHF, da utilizzare in ambienti industriali e magazzini a ridosso di baie di carico, per la gestione di identificazione automatica delle procedure logistiche di inbound e outbound.

E’ possibile realizzare anche varchi RFID su linee di produzione per monitorare lo spostamento di pezzi e prodotti.

RFID E SETTORI DI APPLICAZIONE

L’RFID è uno strumento molto diffuso in campo industriale, andiamo ora ad analizzare le seguenti applicazioni possibili, suddivise per tipologia di utilizzo:

- Tracciabilità –> identificare in maniera univoca un’entità. Seguire gli spostamenti delle materie prime e dei i semilavorati su bancali movimentati da carrelli elevatori o muletti in genere.

- Inventario –> al fine di contenere il costo di esecuzione degli inventari. Verificare la presenza o meno di un attrezzo o di una materia prima all’interno degli armadi e scaffalature.

- Identificazione del prodotto –> tracciabilità di oggetti univocamente identificabili. Riconoscimento e identificazione dei componenti da lavorare.

- Prevenzione frodi –> assegna ad ogni oggetto un’ etichetta univoca, non leggibile da chi non è autorizzato

- Controllo accessi –> rilevazione presenze collegata al software di gestione del personale.

- Spedizioni -> Lettura dei bancali caricati su camion attraverso gate.

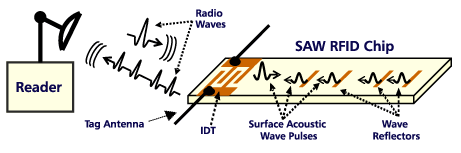

RFID SAW

I sistemi RFID basati su SAW hanno la capacità intrinseca di misurare la posizione del tag, la direzione di movimento e la temperatura del tag; funzionalità che per i normati tag RFID sono costose o difficili da implementare. Inoltre, i tag RFID SAW, possono essere letti anche attraverso pareti metalliche (fino ad un certo spessore), possono resistere a temperature operative elevate, raggi X ad alta energia e sterilizzazione a raggi gamma.

Il tag RFID SAW utilizza un chip intrinsecamente più economico in combinazione con un’antenna tag più piccola e meno costosa, il che si traduce in un sostanziale vantaggio in termini di costi rispetto ai tag basati su IC tradizionali.

Caratteristiche principali dei Tag RFID SAW:

- Supera i numerosi limiti dei chip RFID basati su IC, inclusi i requisiti di alimentazione e le limitazioni delle prestazioni;

- Può funzionare in tutto il mondo nel rispetto delle normative del settore RF;

- È significativamente più conveniente rispetto ai chip RFID tradizionali basati su IC;

- Fornisce un numero praticamente illimitato di codici di identificazione;

- Fornisce un raggio di lettura superiore mantenendo letture precise e ad alta velocità.

Funzionamento del sistema RFID SAW:

Il lettore emette un impulso di onde radio che viene convertito direttamente in un’onda acustica di superficie su nanoscala sulla superficie del chip SAW dall’IDT (trasduttore interdigitale). Quell’onda acustica viaggia oltre una serie di riflettori d’onda per produrre impulsi d’onda acustica codificati in modo univoco, che ritornano all’IDT. L’IDT converte questi impulsi in un segnale di risposta a onde radio codificate che viene inviato al lettore. Il chip SAW funziona utilizzando l’effetto piezoelettrico e non richiede alimentazione CC.